By Esabda

Are you interested in venturing into the exciting world of 3D printing? Starting a 3D printing business can be a rewarding and profitable endeavor. As the demand for 3D printed products continues to rise, there are numerous opportunities for entrepreneurs to capitalize on this technology. In this article, we will guide you through the essential steps to start your 3D printing business successfully.

In this section, we will provide an overview of the 3D printing industry and highlight the potential opportunities it offers to entrepreneurs. We will delve into the benefits of starting a 3D printing business and the growing demand for customized and innovative products.

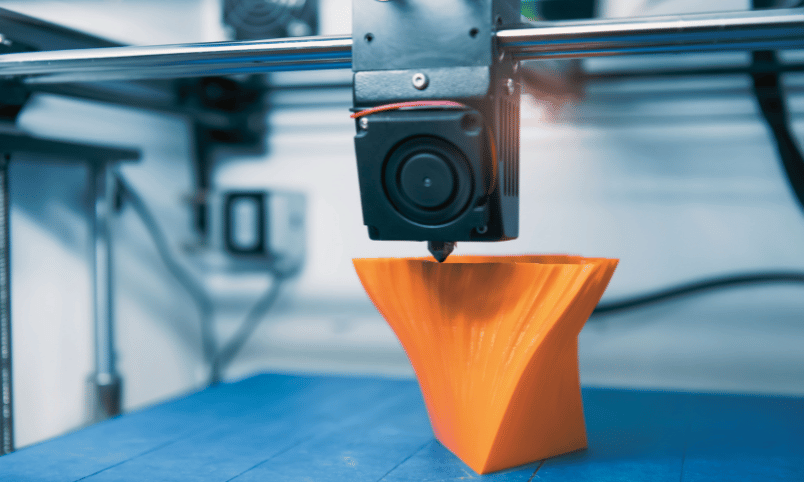

What is 3D Printing?

3D printing, also known as additive manufacturing, is a revolutionary technology that allows the creation of three-dimensional objects layer by layer based on a digital design. Unlike traditional manufacturing methods that involve subtractive processes like cutting or shaping materials, 3D printing builds objects by adding successive layers of materials, such as plastics, metals, or even biological materials.

The process begins with a 3D model created using computer-aided design (CAD) software or obtained from 3D scanning. This digital model is then sent to a 3D printer, which interprets the design and constructs the object layer by layer using the selected material.

With its versatility, speed, and ability to produce complex geometries and customized products, 3D printing has found applications in various industries, including manufacturing, healthcare, aerospace, automotive, architecture, and consumer products, revolutionizing the way we design, prototype, and manufacture objects.

Start a Successful 3D Printing Business in 12 Steps

Here are the 12 steps to guide you start a profitable 3D printing business:

1. Researching the Market

To start a successful 3D printing business, it’s crucial to conduct thorough market research. This involves identifying the current trends, competitors, and potential target markets. By understanding the market landscape, you can tailor your business strategy to meet the demands of customers effectively.

2. Identifying Target Audience

Knowing your target audience is essential for any business. In this section, we will discuss the importance of defining your target audience and how to identify potential customers for your 3D printing services. By catering to specific niches or industries, you can position your business as an expert in those areas and attract the right clientele.

3. Choosing the Right 3D Printing Technology

There are various 3D printing technologies available, each with its own strengths and limitations. This section will explore different types of 3D printers, such as fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). We will help you understand the factors to consider when choosing the most suitable technology for your business.

4. Acquiring the Necessary Equipment

To give a great start to your 3D printing business investing in the right equipment is crucial to delivering high-quality 3D printed products. Here, we will guide you through the process of selecting the necessary hardware, software, and materials required for your 3D printing business. We will also discuss budget considerations and potential financing options.

5. Setting Up Your Workspace

Creating an efficient and organized workspace is essential for maximizing productivity. In this section, we will provide tips on setting up your 3D printing workspace, including considerations for ventilation, storage, and workflow optimization. A well-designed workspace can enhance operational efficiency and ensure a smooth production process.

6. Selecting Suitable Materials

The choice of materials plays a significant role in 3D printing. Different applications require specific materials with varying properties. This section will cover popular materials used in 3D printing, such as PLA, ABS, and nylon, and guide you in selecting the right materials for your target market and intended applications.

7. Designing and Prototyping

Design and prototyping are crucial stages in the 3D printing process. Here, we will explore design software options and discuss the importance of creating 3D models that are compatible with your chosen 3D printing technology. We will also delve into the iterative prototyping process, allowing you to refine your designs before moving on to the final production stage.

Also Read: 20 Profitable 3D Printing Business Ideas

8. Pricing Your Services

Determining the right pricing strategy is vital for the success of your 3D printing business. This section will guide you through the process of setting competitive prices while considering factors such as material costs, production time, complexity of designs, and market demand. We will also discuss different pricing models and how to calculate your profit margins effectively.

9. Marketing and Promoting Your Business

In order to attract customers and generate sales, effective marketing and promotion are essential. This section will provide valuable insights on developing a comprehensive marketing plan for your 3D printing business. We will explore various marketing channels, including online platforms, social media, industry events, and collaborations with influencers or complementary businesses.

10. Building a Strong Online Presence

In today’s digital age, establishing a strong online presence is vital for the success of any business. Here, we will discuss the importance of creating a professional website, optimizing it for search engines (SEO), and utilizing social media platforms to showcase your 3D printing capabilities. Building a reputable online brand will help you reach a wider audience and attract potential clients.

Also read: 100 Effective Small Business Marketing Ideas

11. Collaborating with Other Businesses

Collaborating with other businesses can be mutually beneficial and open up new opportunities for growth. This section will explore strategic partnerships, joint ventures, and outsourcing possibilities in the 3D printing industry.

By leveraging the strengths of others and forming strategic alliances, you can expand your capabilities and reach new markets. After giving a good start to your 3D printing business collaborating with other business will help you stay stable in the industry.

12. Providing Excellent Customer Service

Customer satisfaction is the cornerstone of any successful business. This section will emphasize the importance of providing exceptional customer service in the 3D printing industry. We will discuss effective communication, timely delivery, post-sales support, and handling customer feedback. By prioritizing customer satisfaction, you can build long-term relationships and secure repeat business.

Is 3D Printing a Profitable Business?

Yes, 3D printing can be a profitable business venture. The increasing demand for customized and innovative products, coupled with advancements in 3D printing technology, presents numerous opportunities for entrepreneurs.

By offering unique services such as rapid prototyping, small-batch production, and personalized items, 3D printing businesses can cater to niche markets and attract customers who value customization and quick turnaround times.

However, like any business, profitability depends on various factors such as market research, pricing strategies, operational efficiency, and effective marketing. By delivering high-quality products, staying updated with industry trends, and providing excellent customer service, a well-managed 3D printing business has the potential to generate significant profits and establish itself as a key player in the industry.

So, with the right approach and a focus on meeting customer needs, 3D printing can indeed be a profitable and rewarding business venture.

How Much Does a 3D Printing Business Make?

The earnings of a 3D printing business can vary significantly depending on various factors such as the scale of operations, target market, services offered, and the overall demand for 3D printing in the specific region or industry. On average, a well-established and successful 3D printing business can earn anywhere from $50,000 to $500,000 or more annually.

However, it’s important to note that these figures are approximate and can vary greatly based on individual circumstances and market conditions. It’s crucial to conduct thorough market research, develop a solid business plan, and continuously adapt to changing industry trends to maximize the earning potential of a 3D printing business.

What are the Initial Costs involved in Starting a 3D Printing Business?

The initial costs involved in starting a 3D printing business can vary depending on several factors such as the type of 3D printing technology, the scale of operations, and the specific services you plan to offer. On average, setting up a 3D printing business can require an investment ranging from $10,000 to $50,000 or more.

When starting a 3D printing business, you can expect the following initial costs:

- 3D Printers: Costs vary based on technology and capabilities, ranging from $500 to several thousand dollars for entry-level and industrial-grade printers.

- Materials: The type and quantity of materials needed for printing will affect costs.

- Software and Licenses: Consider the cost of design software, ranging from free options to licensed professional software.

- Workspace and Equipment: Allocate funds for renting or buying a workspace, setting up workbenches, ventilation, safety equipment, and purchasing necessary tools.

- Marketing and Branding: Budget for website development, online marketing, social media campaigns, branding materials, and industry event participation.

- Consumables and Maintenance: Account for ongoing expenses such as materials, printer maintenance, replacement parts, and consumables.

Conclusion

Congratulations on taking the first step towards starting a 3D printing business! It’s an exciting venture that requires careful planning, extensive research, and unwavering dedication. By incorporating the strategies shared in this article on “How to Start a 3D Printing Business,” you’re already on your way to success.

Remember, the key lies in delivering exceptional products and services while embracing the endless opportunities offered by 3D printing technology. So, gear up, follow the guidelines provided, and get ready to embark on a fulfilling entrepreneurial journey filled with innovation, creativity, and endless possibilities. Your journey in the world of 3D printing starts now!

FAQs (How to Start a 3D Printing Business)

The learning curve for 3D printing can vary based on individual factors such as prior experience with design software and technical aptitude. However, with dedication and practice, you can acquire the necessary skills within a few months. There are numerous online tutorials, courses, and communities available to help you learn the fundamentals of 3D printing. Continuous learning and staying updated with advancements in the field will contribute to your expertise and proficiency over time.

Yes, 3D printing is environmentally friendly in certain aspects. It reduces waste by using only the necessary amount of material for each object and supports local manufacturing, minimizing carbon emissions from transportation. However, the environmental impact of materials, especially plastics, should be considered. Efforts are underway to develop more sustainable materials and processes in the 3D printing industry as the technology continues to evolve.

No, 3D printing is not generally suitable for mass production due to limitations in speed and cost. Traditional methods like injection molding are more efficient for large-scale production of identical items. However, 3D printing is ideal for customized, complex, and low-volume parts or products. It excels in rapid prototyping, small-batch production, and on-demand manufacturing, making it valuable for niche markets, product development, and customization.

Also Read:

- Artificial Intelligence in Food Industry | Applications And Trend

- How to Create Digital Downloads for Etsy | Create and Sell

- How to Start a Craft Business in 2023

- How to Start a Luggage Delivery Business | Complete Guide